Solids or liquids that easily release oxygen or even other oxidizing gases (such as chlorine, bromine, or fluorine) are known as oxidizing materials. They also consist of substances that chemically oxidize combustible (burnable) substances, in which oxygen reacts chemically with another substance, raising the possibility of fire or explosion. This reaction can happen spontaneously at ambient temperature or when lightly heated. Strong fire and explosion risks can arise from oxidizing liquids and solids. By burning or oxidizing flammable materials or fluids in the exhaust air stream, oxidizers are pollution control devices that process exhaust air streams. They then discharge the harmful-free gases into the environment. Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr CTS Inc. is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

More Oxidizer Manufacturers

Industrial air pollution remains a critical concern for businesses across manufacturing, chemical processing, pharmaceuticals, and more. The cornerstone of effective air pollution control is the efficient removal of hazardous airborne contaminants, especially particulate matter (PM), volatile organic compounds (VOCs), and toxic air pollutants (TAPs). Advanced oxidizer systems—such as thermal oxidizers and catalytic oxidizers—are designed to combust or chemically react with these pollutants, transforming them into non-toxic byproducts like water vapor and carbon dioxide. While no system can guarantee 100% removal of all air pollutants, the byproducts created by industrial oxidizer technology are significantly less harmful, easier to manage, and ensure regulatory compliance with environmental standards.

What Are Oxidizers? Understanding Their Role in Air Pollution Control

Oxidizers are sophisticated pieces of air pollution control equipment used to destroy hazardous air pollutants and reduce industrial emissions. They achieve this by utilizing high temperatures and/or catalysts to oxidize contaminants present in process exhaust streams. The result is the conversion of dangerous substances—such as VOCs and TAPs—into carbon dioxide, water, and other innocuous compounds. Industries searching for VOC abatement solutions and effective industrial emission control commonly turn to oxidizer systems for reliable, high-efficiency performance.

Operation of Oxidizers: How Do Industrial Oxidizer Systems Work?

Although highly engineered, the working principle of oxidizers is remarkably straightforward. Contaminated air, often generated by industrial processes such as coating, printing, painting, chemical manufacturing, or pharmaceutical production, is introduced into the oxidizer’s primary chamber. Within this chamber, the air stream is subjected to either high temperatures (in thermal oxidizers) or lower temperatures in the presence of a catalyst (in catalytic oxidizers). This process triggers the combustion or chemical reaction of hazardous compounds, breaking them down into less harmful byproducts. The resulting emissions are then filtered or safely released—meeting or exceeding local, national, and international air quality regulations.

There are two main categories of oxidizers widely used for air pollution control:

- Thermal oxidizers—which include direct-fired, regenerative, and recuperative types, utilize extremely high temperatures for pollutant destruction.

- Catalytic oxidizers—which employ catalysts such as platinum, palladium, or rhodium to promote oxidation at much lower temperatures, reducing energy consumption.

Additionally, rotor concentrator-based oxidizers are becoming more prevalent for treating large-volume, low-concentration air flows. These systems use a continuously rotating wheel impregnated with adsorbent material to concentrate pollutants before oxidation, significantly improving overall destruction efficiency.

Key Decision Factors: Choosing the Right Oxidizer for Your Facility

When evaluating industrial oxidizer solutions, it’s crucial to consider multiple factors to ensure optimal performance and cost-effectiveness:

- Type and concentration of pollutants in the process air stream (e.g., high-VOC, TAPs, odorous compounds, particulates, etc.)

- Required destruction removal efficiency (DRE) to remain compliant with air quality standards and emission limits

- Airflow volume and process temperature that the oxidizer will handle

- Energy efficiency—including the potential for heat recovery via regenerative or recuperative designs

- Maintenance requirements and projected operational costs

- Space constraints and integration needs with existing facility infrastructure

- Regulatory compliance—meeting EPA, OSHA, and local environmental regulations for air emissions

Are you looking for a high-efficiency oxidizer system tailored to your industrial application? Use our comprehensive comparison tool to evaluate leading oxidizer manufacturers, review system capabilities, and request detailed proposals based on your unique emission control requirements.

Types of Oxidizers: Industrial Air Pollution Control Technologies

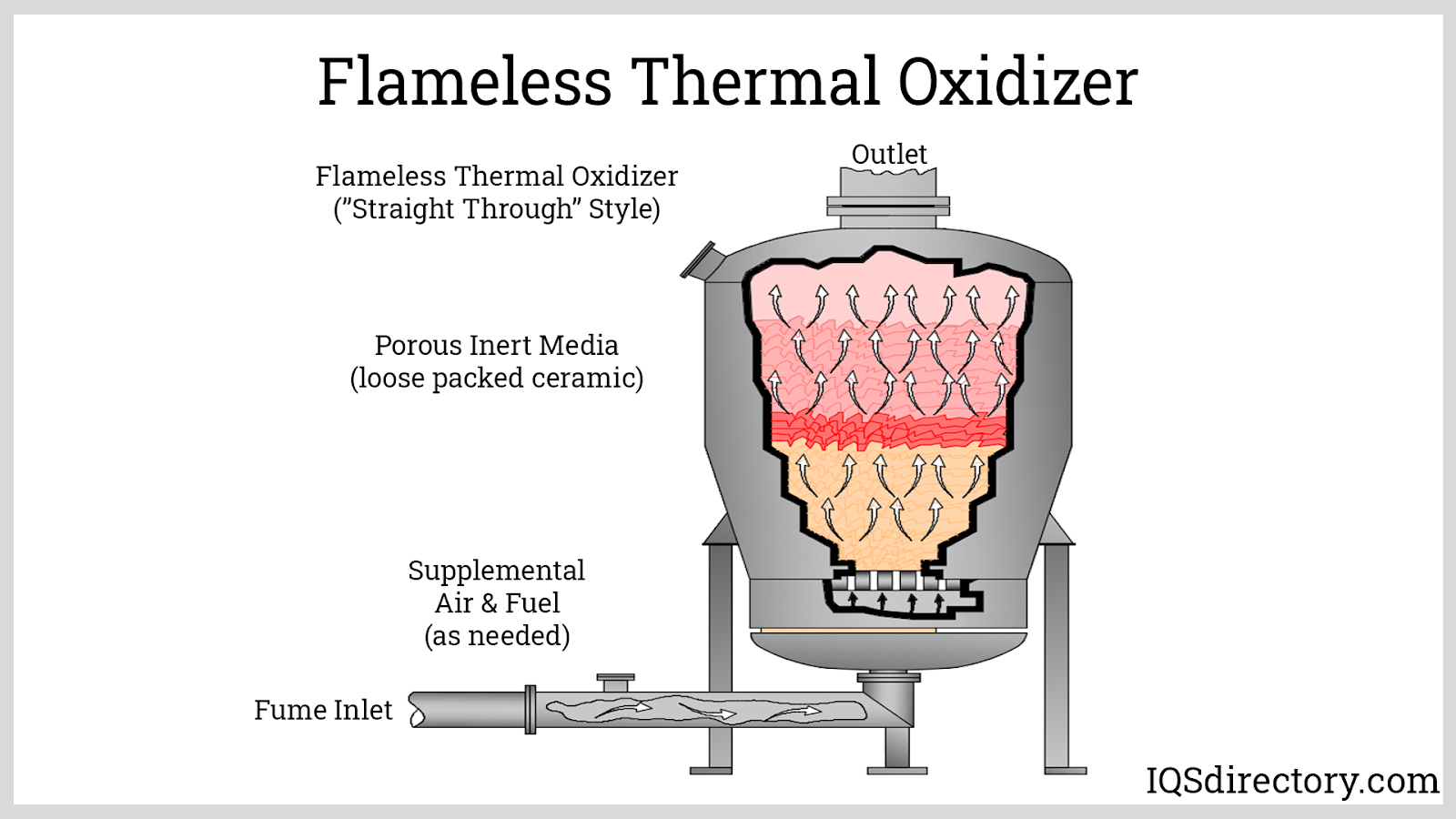

Thermal Oxidizers: Direct-Fired, Recuperative, and Regenerative Designs

Thermal oxidizers are the most widely used air pollution control systems for the destruction of VOCs, hazardous air pollutants (HAPs), and odorous emissions. These systems operate by raising the temperature of contaminated air streams to between 800°F and 2,000°F, causing the organic and inorganic compounds to combust. The primary subcategories include:

- Direct-fired thermal oxidizers (afterburners)—Simple in design, these units introduce contaminated air directly to a flame within the combustion chamber. The gases are maintained at high temperatures for a specified “residence time” to ensure complete destruction. Afterburners are ideal for applications with high pollutant concentrations and require minimal maintenance.

- Recuperative thermal oxidizers—These systems utilize a heat exchanger to preheat incoming air using heat recovered from the oxidizer’s exhaust. This process reduces fuel consumption and lowers operational costs, making them suitable for continuous processes with moderate pollutant loading.

- Regenerative thermal oxidizers (RTOs)—RTOs are advanced systems that maximize energy recovery by using a ceramic heat exchange media. The contaminated air passes through beds of ceramic material, which absorb and release heat, dramatically increasing energy efficiency. RTOs are commonly deployed in industries with large air volumes and low-to-moderate VOC concentrations, such as printing, painting, and pharmaceutical manufacturing.

Catalytic Oxidizers: Energy-Efficient VOC Abatement

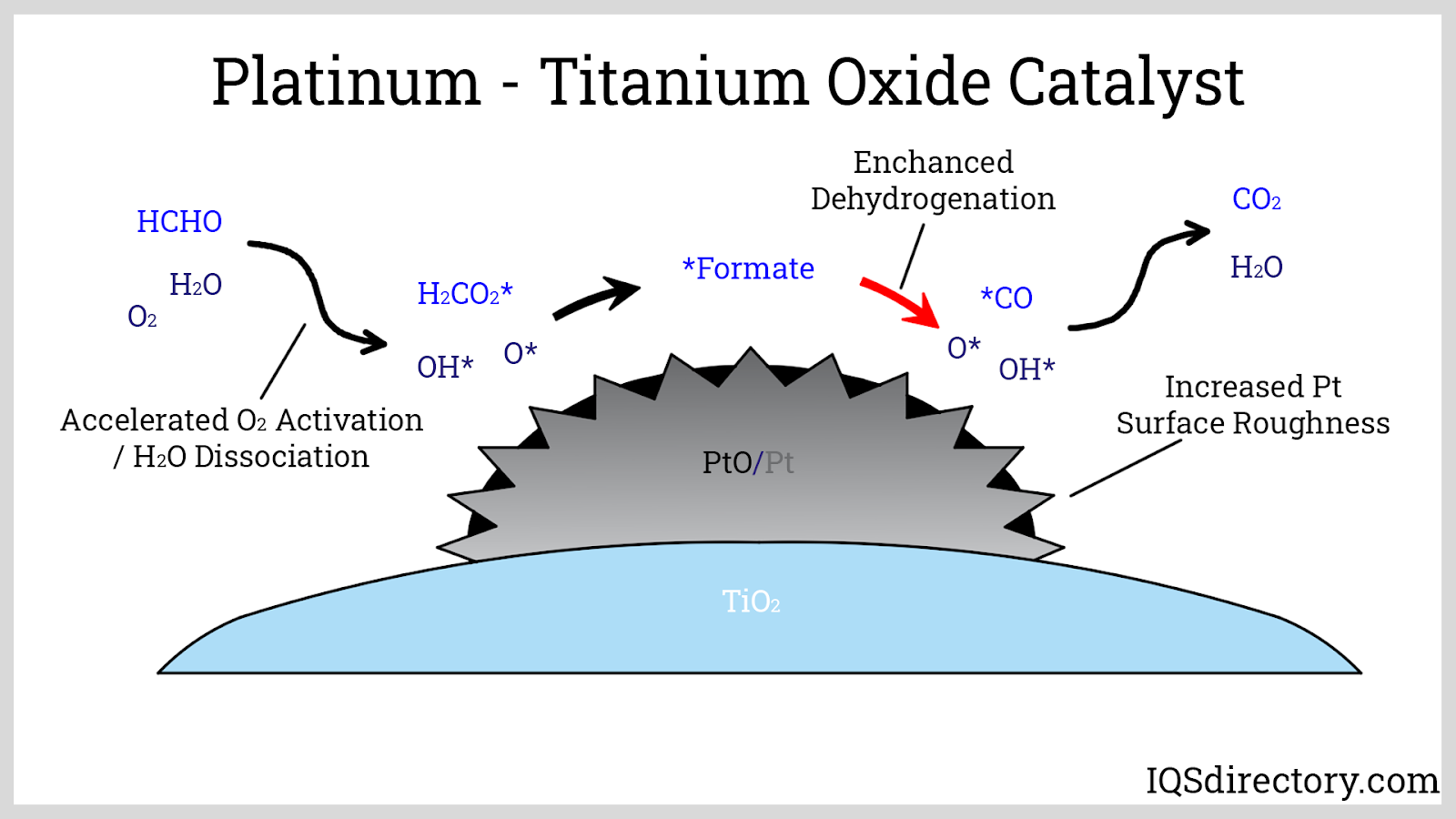

Catalytic oxidizer systems, also known as catalytic incinerators, operate similarly to thermal oxidizers but utilize a catalyst to promote oxidation at lower temperatures (typically 644°F to 1,004°F). The catalyst—often made from precious metals such as platinum or rhodium—facilitates the reaction, enabling significant reductions in fuel consumption and carbon footprint.

- Lower operating temperatures mean less fuel is required, resulting in lower operating costs.

- High destruction removal efficiency (DRE) for VOCs and some odorous compounds.

- Ideal for processes with moderate VOC concentrations and consistent air flow rates, such as coating, laminating, and chemical production.

When evaluating catalytic oxidizers, businesses should consider the compatibility of the process stream with the catalyst, as some contaminants may poison or deactivate the catalyst over time.

Direct-Fired Thermal Oxidizers: Simple and Robust Air Pollution Control

Direct-fired thermal oxidizers, or afterburners, represent the most straightforward approach to industrial air stream treatment. By exposing contaminated process gases to a direct flame in the firebox, these units achieve rapid oxidation of hazardous components. They operate at extremely high temperatures—often 1,800°F to 2,190°F—and support airflow rates from 0.24 to 24 cubic meters per second, making them suitable for high-volume or highly concentrated air pollution control scenarios.

Regenerative Thermal Oxidizers (RTO): Maximizing Energy Recovery

Regenerative thermal oxidizers (RTOs) are among the most energy-efficient options for industrial emission control. RTOs utilize ceramic beds to preheat incoming air, capturing and recycling heat from the oxidation process. This design enables RTOs to operate at lower temperatures (typically 1,400°F to 1,510°F) compared to direct-fired systems, drastically reducing fuel usage and greenhouse gas emissions. RTOs are recommended for industries with continuous or high-volume exhaust streams, such as food processing, automotive manufacturing, and electronic component production.

Rotor Concentrator-Based Oxidizers: Advanced VOC Control

Rotor concentrator-based oxidizers combine adsorption and thermal oxidation for high-efficiency VOC abatement. These systems use a rotating wheel coated with adsorbent materials to concentrate dilute VOC-laden air streams before routing them to a thermal oxidizer. Rotor concentrators are ideal for applications where air volumes are large but VOC concentrations are low, such as semiconductor manufacturing, painting, and printing operations. By concentrating pollutants, these systems reduce the size and energy requirements of downstream oxidizers, offering a cost-effective solution for challenging emission profiles.

Oxidizer Applications: Where Are Industrial Oxidizer Systems Used?

Oxidizer systems are vital to air pollution control in a wide range of industries. Typical applications include:

- Chemical processing—Destruction of hazardous air pollutants (HAPs) and VOCs generated from chemical reactions and solvent use.

- Pharmaceutical manufacturing—Control of process emissions, odorous compounds, and hazardous byproducts.

- Automotive painting and coating—Removal of paint fumes, solvents, and particulate matter to comply with environmental regulations.

- Food processing—Control of odors and airborne organic compounds produced during cooking, baking, or flavoring operations.

- Electronics and semiconductor fabrication—VOC abatement and toxic gas destruction from cleaning, etching, and photolithography processes.

- Printing, laminating, and flexible packaging—VOC and HAP removal from inks, adhesives, and coatings used in high-speed production lines.

- Petrochemical and refinery operations—Destruction of hydrocarbon vapors and odorous emissions to meet stringent air quality standards.

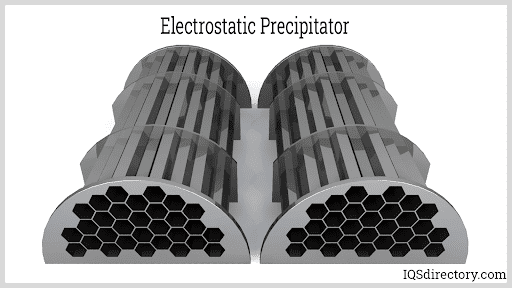

Many facilities also combine oxidizers with other wet scrubbers, electrostatic precipitators, and filtration systems to achieve comprehensive air pollution control and minimize overall environmental impact.

Benefits of Industrial Oxidizer Systems

When properly specified and maintained, oxidizer systems deliver a range of business and operational benefits:

- High destruction efficiency for VOCs, HAPs, and odorous compounds—often exceeding 99% DRE

- Regulatory compliance with EPA, state, and local air quality standards—reducing the risk of fines and production interruptions

- Energy savings and reduced carbon footprint through heat recovery and advanced system designs such as RTOs and rotor concentrators

- Flexibility to handle a wide range of process conditions, air volumes, and pollutant profiles

- Reliable, low-maintenance operation—especially with robust designs and high-quality materials

- Improved workplace safety and community relations by minimizing fugitive emissions and odors

Curious about how an oxidizer system could transform your facility’s air quality and compliance profile? Explore case studies, request a free consultation, or ask for a custom ROI analysis from our network of expert oxidizer manufacturers.

How to Choose the Best Oxidizer Manufacturer or Supplier

Selecting the right oxidizer supplier is crucial to the long-term success of your emission control strategy. Consider the following best practices when sourcing industrial oxidizer solutions:

- Request and compare proposals from at least 5–6 reputable oxidizer manufacturers using our verified supplier directory.

- Assess each manufacturer’s industry experience, reference installations, and technical expertise in your specific application area.

- Review detailed product literature, technical specifications, and case studies to understand system capabilities and performance.

- Use our website previewer to quickly compare supplier websites and identify the best match for your requirements.

- Utilize our RFQ (Request For Quote) form to contact multiple suppliers simultaneously—streamlining your evaluation process.

For a comprehensive approach, connect directly with manufacturers’ engineering teams to discuss custom solutions, integration support, and after-sales service options. Leading suppliers can provide turnkey installation, commissioning, and ongoing maintenance packages to ensure peak system performance and reliability.

Frequently Asked Questions About Industrial Oxidizers

- What is the difference between a thermal oxidizer and a catalytic oxidizer?

Thermal oxidizers rely on high temperatures to combust pollutants, while catalytic oxidizers use a catalyst to enable oxidation at lower temperatures, resulting in energy savings and lower operational costs. - How do I determine the right size and type of oxidizer for my application?

Key considerations include process air flow rate, pollutant type and concentration, required destruction efficiency, available utilities, and integration needs. Consulting with experienced oxidizer manufacturers is recommended for proper system sizing and selection. - What maintenance is required for an industrial oxidizer?

Routine inspections, cleaning of heat exchange media or catalyst beds, burner tuning, and monitoring of emissions are common maintenance tasks. Some systems feature advanced controls for predictive maintenance and remote diagnostics. - Can oxidizers be integrated with other air pollution control technologies?

Yes, oxidizers are often combined with wet scrubbers, particulate filters, and electrostatic precipitators for comprehensive emission abatement. - What are the key benefits of regenerative thermal oxidizers (RTOs)?

RTOs offer high energy efficiency, low operating costs, and superior VOC/HAP destruction rates—making them ideal for large-volume, low-concentration exhaust streams.

Next Steps: Find the Right Oxidizer System for Your Needs

Ready to enhance your facility’s air quality, achieve regulatory compliance, and minimize operational costs? Start by exploring our list of vetted oxidizer suppliers and oxidizer manufacturers. Whether you need a custom-designed regenerative thermal oxidizer, a turnkey catalytic oxidizer solution, or advice on integrating rotor concentrator technology, our industry experts can help.

Use our easy-to-navigate supplier directory, read in-depth product guides, and request tailored quotes to compare options. For technical support or to schedule a site assessment, contact our team for personalized recommendations.

Related Air Pollution Control Technologies

- Wet Scrubbers

- Electrostatic Precipitators

- Baghouse Dust Collectors

- Cartridge Dust Collectors

- Industrial Air Purifiers

For more information, in-depth guides, or to begin your search for the best oxidizer system for your facility, contact our experts or browse our educational resources. Achieve cleaner air, a safer workplace, and peace of mind with the right industrial air pollution control solution.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services