Scrubbers are liquid-based air pollution management systems that remove particulate matter and gasses from an industrial exhaust or flue gas stream. This atomized liquid (usually water) entrains particles and polluting gasses, effectively washing them out of the gas stream. Read More…

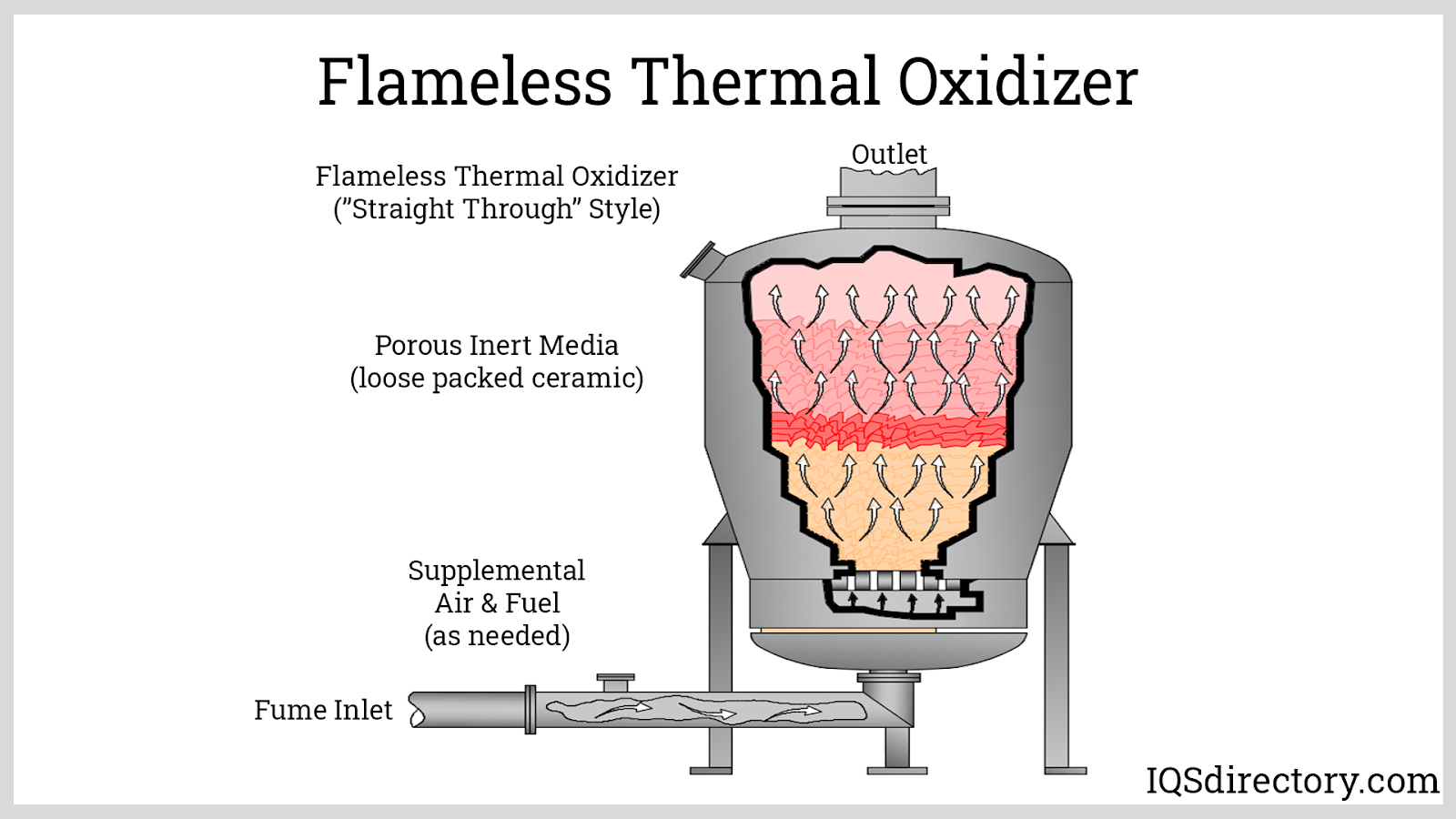

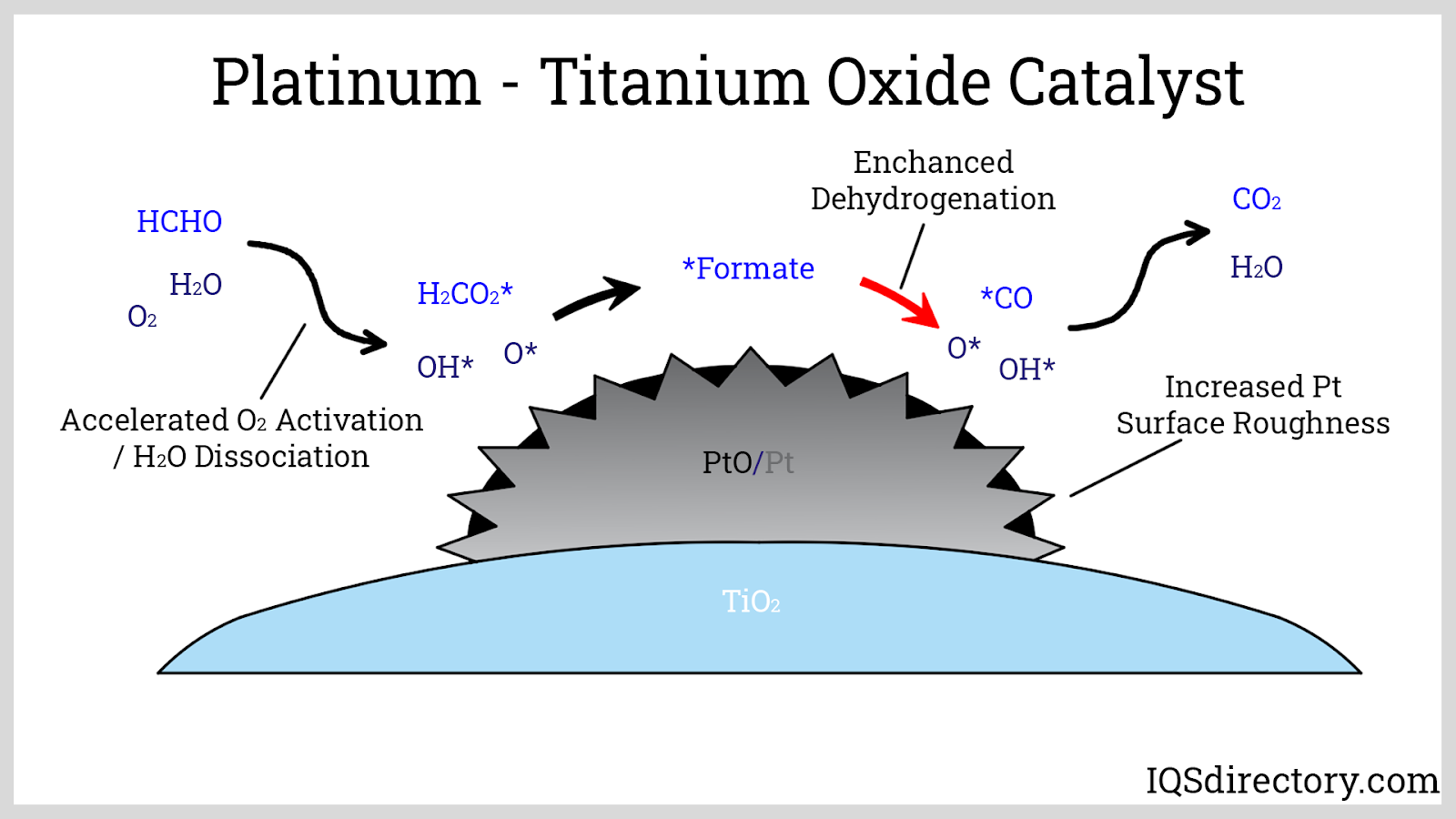

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr CTS Inc. is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

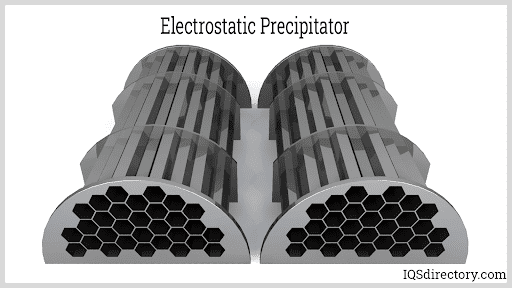

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

We are Process Combustion Corporation, and we specialize in designing, engineering, and delivering advanced air pollution control solutions for industrial and commercial operations that demand reliable environmental compliance and long-term performance. Our work centers on helping manufacturers reduce harmful emissions, control particulate matter, and manage volatile organic compounds through...

More Air Pollution Scrubber Manufacturers

Scrubbers are quite diverse in contrast to other air pollution management systems, having the capacity to remove particulates, mists, and gasses while also providing cooling. They can also safely handle explosive and flammable gasses. Scrubbers, on the other hand, are prone to corrosion and create slurry waste streams that are difficult to recycle and remove.

Types of Air Scrubbers

Scrubbers come in various shapes and sizes, each with its function and effectiveness.

Spray Towers

Gas streams are pumped into a chamber and interact with cleansing liquid created by spray nozzles in spray towers or spray partitions. Spray towers have a low power usage but poor particle collecting efficiency.

Cyclone Spray Chambers

These scrubbers combine the cyclone and spray tower capture systems. Gas streams usually enter the chamber at high speeds, tangentially.

Venturi Scrubbers

Scrubbers with a venturi-shaped chamber with converging and diverging parts are known as venturi scrubbers. Water is pumped at low pressure into the venturi's throat, where the gas stream travels at high speeds.

Orifice Scrubbers

These are comparable to venturi scrubbers. Before entering the aperture, the gas passes through pools of cleaning liquid at high speeds. Droplets and contaminants are eliminated as it escapes by colliding with a series of baffles.

Impingement/Perforated Plate Scrubbers

Impingement/Perforated Plate Scrubbers are a type of orifice scrubber. Gas streams enter the device from the bottom and travel through a perforated tray that contains or is sprayed with a layer of liquid.

Packed Bed Scrubbers

These scrubbers, predominantly gas absorbers, are the most effective for treating gas streams containing gaseous contaminants.

Dry Scrubbers

Dry scrubbers utilize no liquids to remove pollutants from exhaust gasses. They use a dry reaction substance called sorbent, such as alkaline slurry, to remove acid from gas by passing the gas through the sorbent dust to optimize binding.

Wet Scrubbers

They are effective air pollution control devices that remove particles or gasses from industrial exhaust streams. A wet scrubber works by putting a scouring liquid into the filthy gas stream, which collects the particles or gasses.

Working of Air Scrubbers

- Scrubbers are pollution-capturing and removal machines that employ a liquid (usually water).

- A cleaning liquid is atomized and distributed into the gas stream through a nozzle or opening.

- Agglomeration, adhesion, or encapsulation causes the droplets to entrain and collect dust particles.

- As a result, the particle size and mass are effectively increased, making them simpler to collect in a following filter or separation operation.

- The scrubbing liquid absorbs and neutralizes gaseous contaminants simultaneously.

- The suspended liquid is usually collected and circulated through the system using mist collectors.

Applications of Air Scrubbers

- High Productivity Dry scrubbers are indicated for applications such as nitric, hydrochloric, sulfuric, and chromic acid, which require little water.

- Flue-gas condensation can recover heat from hot gasses in scrubbers.

- They're also employed in solar, PV, and LED applications requiring large fluxes.

- Dry scrubbers are typically used to remove acids from gasses.

- Wet scrubbers are used in various industrial settings, including pollution reduction in food processing plants and petroleum refineries.

Benefits of Air Pollution Scrubbers

- Air pollution scrubbers have low-risk handling of flammable and explosive dust.

- A single unit absorbs gas and collects dust.

- Air scrubbers allow hot gasses to cool down.

- Corrosive gasses and dust can be neutralized.

- They are compact and can typically be adapted into existing collecting systems.

- Venturi scrubbers are easy to install and maintain and have a high collecting efficiency for particle pollutants.

- Cyclone spray chambers are cost-effective and need little liquid.

Choosing the Best Air Pollution Scrubber

These are the most critical criteria for an industrial buyer to consider when choosing a scrubber for their application.

Airflow - The allowable gas stream flow rate or range of flow rates through the scrubber is defined by airflow, measured in cubic feet per minute.

Liquid - Refers to the scrubber liquid's planned flow rate, usually expressed in gallons per minute. It controls how much water the scrubber uses, significantly influencing the system's operational expenses.

Minimum Particle Size - The least diameter of particulate matter that a dust collector can capture, measured in micrometers. This rating effectively defines the capabilities of the collection equipment.

Capture Rate - The proportion of particle matter or gaseous pollutants in the scrubber's filtered gas stream is efficiently removed.

In addition to performance criteria, material compatibility and operating temperature are two more factors to consider when selecting the best air pollution scrubber.

Material compatibility – It's critical that the materials employed in the scrubber's construction be compatible with the gas stream's chemical and physical qualities.

Operating temperature – Scrubbers are built to cool or quench hot gas streams; they are limited to a particular temperature range, beyond or below which they may not function efficiently.

Choosing the Proper Air Pollution Scrubbers Manufacturer

To make sure you have the most positive outcome when purchasing Air Pollution Scrubbers from an Air Pollution Scrubbers Manufacturer, it is important to compare at least 6 Manufacturers using our list of Air Pollution Scrubbers companies. Each Air Pollution Scrubbers Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Air Pollution Scrubbers business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Air Pollution Scrubbers businesses with the same quote.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

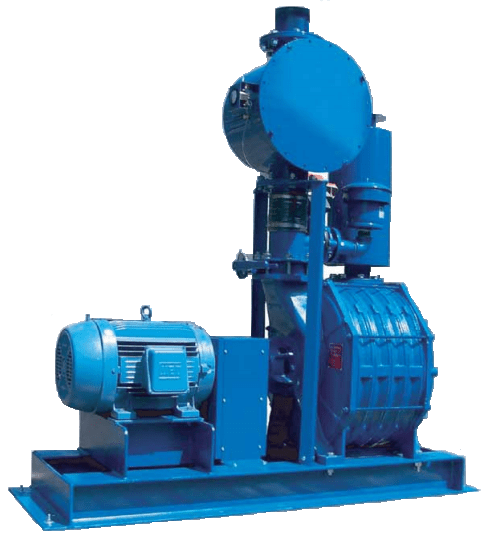

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services