Mist and fume collectors minimize the quantity of mist, aerosols, and fumes in the workplace. They can remediate media streams containing liquid/vapor or solid/vapor mixtures. Mist and fume collectors are frequently used in conjunction with machining equipment and other devices that produce oil mists, plumes of smoke, or debris during operation. They are usually constructed as either source collectors to directly catch material or ambient collectors to treat air as it flows through an area.Read More…

Anguil Environmental provides highly-engineered, environmental equipment and service solutions that help clients solve complex industrial air pollution control and wastewater treatment challenges across the globe. Anguil air pollution control systems include thermal and catalytic oxidation technologies for compliance with VOC, HAP and odor regulations.

Dürr CTS Inc. is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies including scrubbers, wet electrostatic precipitators, thermal and catalytic oxidizers, and solvent recovery systems.

The CMM Group provides design and build, and technical engineering services for VOC emission control, odor abatement solutions and energy recovery systems. CMM Aftermarket Services team provides preventive maintenance and inspection services, controls upgrades, retrofit and rebuild services to extend the life of existing equipment. For small or large, complex projects, The CMM Group’s extensive ...

Pollution Systems designs, manufactures and installs highly reliable industrial air pollution control equipment. We offer Thermal Oxidizers, Catalytic Oxidizers, Regenerative Thermal Oxidizers, Direct Fired Oxidizers, Enclosed Flares, Gas Scrubbers, Particulate Scrubbers, Rotor Concentrators and Heat Recovery Systems. On-site services through our dedicated service company include equipment...

Meet stringent environmental regulations with Ducon's complete line of the most advanced air pollution control equipment: cyclones, scrubbers, incinerators, electrostatic precipitators, activated carbon absorbers, gas absorption towers, flue gas desulfurization, chemical strippers, NOx & VOC Control, etc.

More Mist Collector Manufacturers

Manufacturers use mist collectors on machine tools to provide cleaner air and a better working environment for shop floor personnel. Smoke, fumes, and sub-micron particles are produced during welding, rubber and plastic processing, high-speed machining with coolants, tempering, and quenching. By limiting the detrimental effects of exposure to metalworking fluids, mist collectors help businesses achieve indoor air quality laws. They also increase part quality in manufacturing by keeping work surfaces clean while lowering maintenance and cleaning expenses.

Materials used for Mist Collectors

- A filter

- Mesh-type coalesces, vane packs, or fabric-like material pads

- A rotor and a perforated drum

- A motor that drives the machine

- Stainless steel units for particular purposes

Types of Mist Collectors

Media Filter Collectors

HEPA-type filters are used to remove industrial mist and smoke oil in these media filter collectors, also known as cartridge mist collectors. A fan or blower draws air carrying fumes or steam into the cartridge medium. The liquid is subsequently driven through the filter, trapping the droplets, mist, and particles.

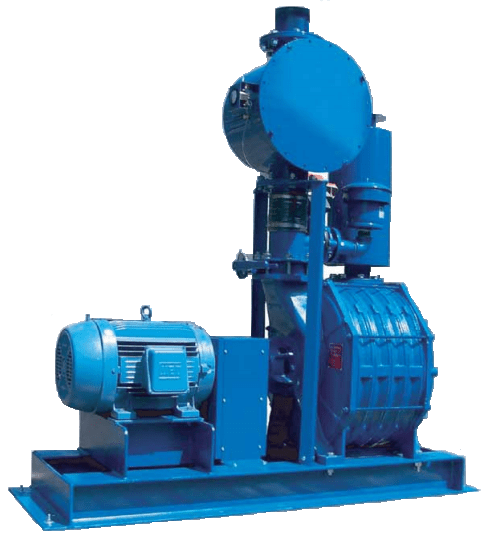

Centrifugal Mist Collectors

Centrifugal mist collectors use revolving filter components to reassemble captured smoke into bigger droplets. The bigger droplets are then driven free of the filter drum and towards the interior wall of the casing, where the revolving centrifugal force eventually eliminates them.

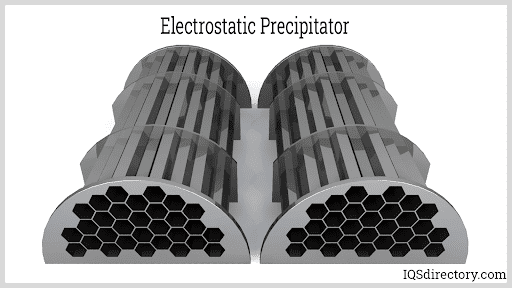

Electrostatic Collector

Electrostatic precipitator mist collectors employ a high voltage to charge and capture tiny mist particles and droplets. Mist or smoke streams enter the collector and travel across one or more high-voltage electrodes. The electrode(s) provide a charge to the particles in the stream, causing them to adhere to plates or surfaces in the system that are oppositely charged.

Construction of Mist Collectors

- Various mist collecting methods are available, each being best depending on the application.

- Each machine needs its motor starter.

- No special motors are required; standard shaft motors are sufficient.

- The collector only requires low motor power for a large volume of air.

- The mist is trapped within a machine tool housing made of metal or plexiglass.

Working of Mist Collectors

- Mist collectors allow liquids to be captured and reused.

- The filter or barrier must be porous, with small mesh-like gaps allowing vapors to flow through.

- Droplets are filtered out through a valve at the bottom of the compartment, while vapors free of mist and debris ascend to the top and depart.

- The collector's base is frequently used as the chamber.

- Additional filtering is accomplished by employing depth-loading fiber bed filters to gather the residual mist particles and consolidate them into a central drain for return to the machine sump.

Benefits of Mist Collectors

- Product purity and throughput are greatly improved, while operating expenses, air pollution, and downstream corrosion dramatically decrease.

- In rare cases, the liquids can be collected and recycled in addition to the pure gas that exits the collector.

- When installed in-line, Mist collectors influence an operating system's gas flow.

- The advantage of centrifugal mist cooling systems is that the smoke oil or mist does not have to drain due to gravity, enabling the compressor to work constantly.

- Furthermore, mist collectors safeguard employees' health by preventing oil mist exposure through skin contact and inhalation.

Applications of Mist Collectors

- Mist collectors are used in various sectors, including metal finishing and forming, chemical processing, brine desalination, marine, food processing, paper and pulp, agricultural, and many more.

- If appropriately constructed, mist collecting systems may be utilized for abrasives, coolant, smoke, oil, water, and other materials.

- Mist collectors are prevalent when vapor quality is critical or reducing space and weight is vital.

- Mist collectors are used in the metalworking industry to collect toxic oil and coolant mist produced during machining.

- Commercial food manufacturing procedures can also utilize mist collectors to eliminate cooking aromas, smoke, grease, and oil moisture from food production facilities and commercial kitchens.

Choosing the Correct Mist Collectors Company

To make sure you have the most productive outcome when purchasing Mist Collectors from a Mist Collectors Supplier, it is important to compare at least 6 Companies using our list of Mist Collectors manufacturers. Each Mist Collectors Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Mist Collectors business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Mist Collectors companies with the same quote.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services